Pumps

- Home

- Pumps

Fluid Transfer

Moving fluids between locations, such as in water supply or fuel transfer.

Pressure Boosting

Increasing fluid pressure to meet system needs, commonly used in water supply and hydraulic systems.

Circulation

Ensuring continuous fluid flow within systems, like in cooling or heating circuits.

Dosing

Accurately controlling and measuring fluid flow, especially in chemical processes.

Types of Pumps

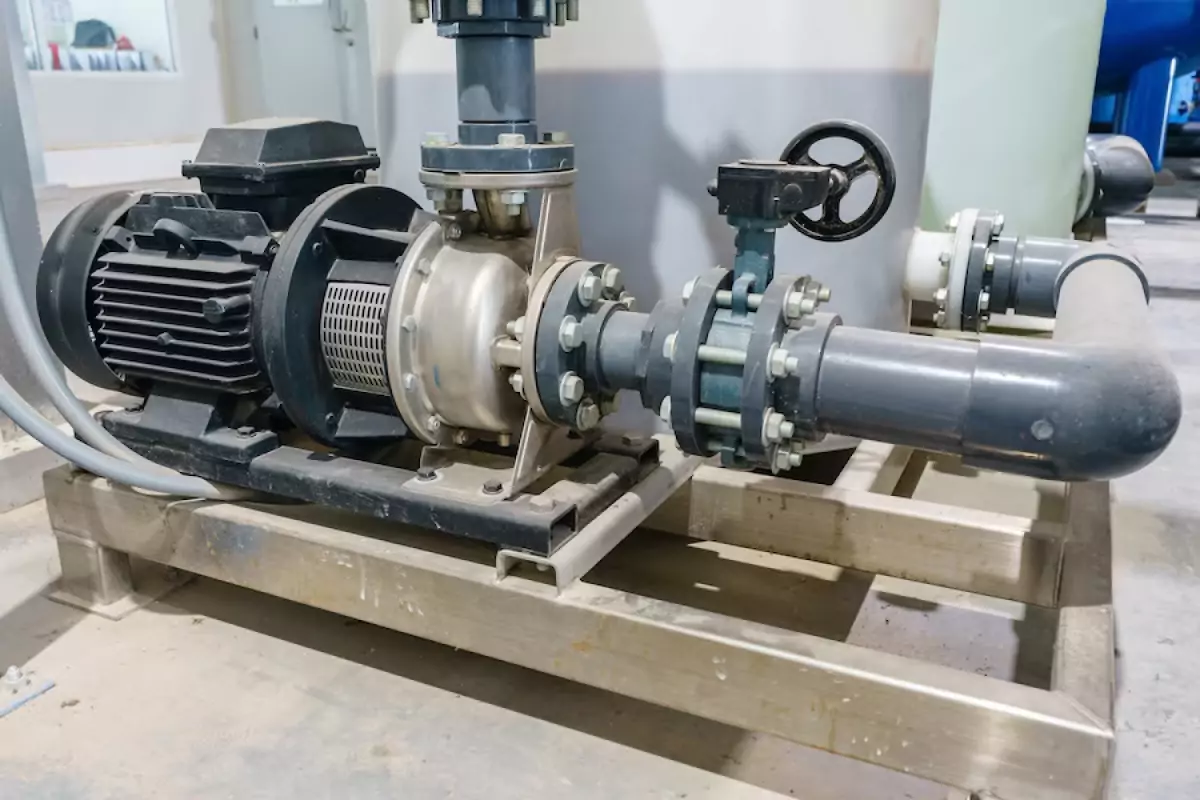

Centrifugal Pumps

Description

Centrifugal pumps use the rotational energy of an impeller to move fluids.

Applications

Found in water supply, wastewater treatment, oil refineries, power plants, and irrigation.

Key Components

⮞ Impeller: Rotates to increase fluid velocity. ⮞ Casing: Houses the impeller and directs fluid flow. ⮞ Shaft: Connects the impeller to the motor. ⮞ Mechanical Seals: Prevent fluid leakage.

Types of Centrifugal Pumps

⮞ Axial Flow: Moves fluid parallel to the shaft. ⮞ Radial Flow: Moves fluid perpendicular to the shaft. ⮞ Mixed Flow: Combines axial and radial flow.

Positive Displacement Pumps

Description

These pumps move fluids by trapping a set amount and forcing it through the system, ensuring a steady flow regardless of pressure.

Applications

Ideal for high-pressure tasks, chemical dosing, hydraulic systems, and fuel injection.

Key Components

⮞ Rotors or Pistons: Displace the fluid mechanically. ⮞ Chambers: Trap and push fluid through the system.

Types of Positive Displacement Pumps

⮞ Rotary Pumps: Use rotating parts (e.g., gear or lobe pumps). ⮞ Reciprocating Pumps: Use pistons or diaphragms to push fluid (e.g., piston or diaphragm pumps). ⮞ Peristaltic Pumps: Use rollers to compress a flexible tube and move fluid.

Diaphragm Pumps

Description

Diaphragm pumps use a flexible diaphragm that moves back and forth to create suction and discharge.

Applications

Often used in chemical processing, food and beverage production, wastewater treatment, and handling corrosive fluids or slurries.

Key Components

⮞ Diaphragm: The flexible membrane that moves fluid. ⮞ Check Valves: Ensure one-way flow of fluid through the pump.

Gear Pumps

Description

Gear pumps are a type of positive displacement pump that move fluid through meshing gears.

Applications

Commonly used in oil transfer, chemical processing, and hydraulic fluid transfer.

Key Components

⮞Gears: Rotate to move fluid through the pump. ⮞ Casing: Encloses the gears and guides fluid flow. ⮞Shafts: Drive the rotation of the gears.

Peristaltic Pumps

Description

Peristaltic pumps, or hose pumps, move fluid by compressing and releasing a flexible tube.

Applications

Common in laboratories, chemical dosing, pharmaceuticals, and the food and beverage industries.

Key Components

⮞ Flexible Tube or Hose: The fluid's pathway. ⮞ Rollers or Shoes: Compress the hose to move fluid. ⮞Drive Mechanism: Rotates the rollers or shoes.

Submersible Pumps

Description

Submersible pumps are designed to operate while fully submerged in the fluid they pump.

Applications

Common in water wells, drainage systems, sewage systems, and deepwater pumping.

Key Components

⮞Motor: Encased in a waterproof housing. ⮞ Impeller or Propeller: Moves the fluid. ⮞ Seals: Prevent fluid from entering the motor compartment.

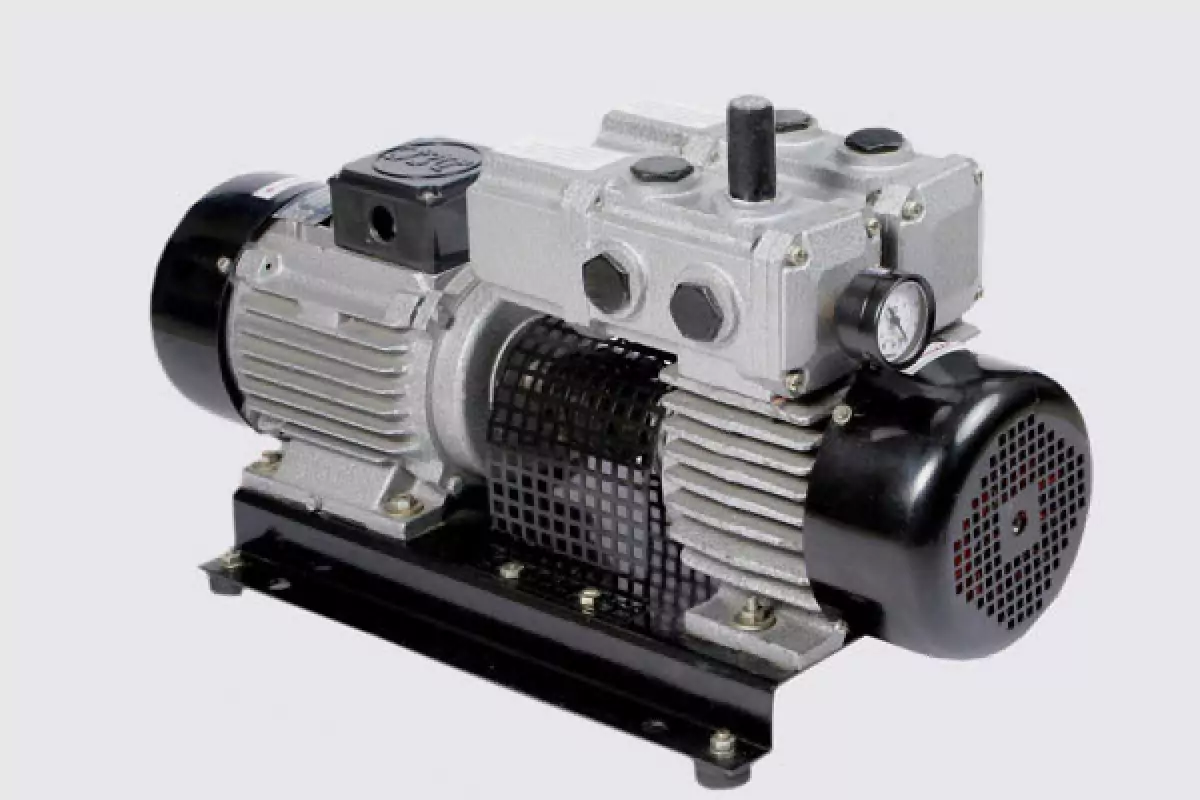

Vacuum Pumps

Description

Vacuum pumps remove air or gas molecules from a sealed volume to create a vacuum.

Applications

Used in vacuum systems, HVAC, laboratories, chemical processing, and food packaging.

Key Components

⮞ Rotors or Vanes: Trap and expel air or gas from the system. ⮞ Chamber: The enclosed space where air or gas is extracted.

Permeate Pumps (Reverse Osmosis)

Description

Boost pumps improve the efficiency of reverse osmosis (RO) systems by reducing back pressure and maximizing water flow.

Applications

Primarily used in water purification systems, particularly in RO setups.

Key Components

⮞ Piston or Diaphragm: Moves water through the RO membrane. ⮞ Check Valves: Ensure proper direction of water flow.

Jet Pumps

Description

Jet pumps use a jet of fluid to create a low-pressure area that draws fluid from a well or reservoir.

Applications

Ideal for shallow wells, water supply, and irrigation.

Key Components

⮞ Nozzle: Directs the fluid jet to create suction. ⮞Venturi: A narrowing tube that increases fluid speed and reduces pressure.

Multistage Pumps

Description

Multistage pumps feature multiple impellers arranged in series to progressively increase fluid pressure at each stage.

Applications

Common in high-pressure applications, boiler feed systems, and water injection in oil fields.

Key Components

⮞ Impellers: Multiple stages of impellers that raise pressure step by step. ⮞ Casing: Encloses the impellers and directs fluid flow.

Common Pump Materials

Description

Pumps are built from various materials depending on the application and the type of fluid being pumped. Some common materials include

⮞ Cast Iron: Widely used in water and low-corrosion applications. ⮞Stainless Steel: Preferred for food processing, pharmaceuticals, and chemicals due to its corrosion resistance. ⮞ Bronze: Often chosen for marine applications because of its resistance to saltwater corrosion. ⮞ Plastic (PVC, Polypropylene, etc.): Perfect for lightweight, corrosion-resistant applications, especially in chemical handling. ⮞ Ceramic or Hard Metal Liners: Typically used in slurry pumps to resist wear from abrasive materials.

Pump Applications

Description

Pumps are used in a wide range of industries, with each type designed to meet specific needs, including:

⮞ Oil & Gas: Used for crude oil transfer, water injection, and refining processes. ⮞ Water & Wastewater: Essential for water supply, sewage treatment, and irrigation systems. ⮞ Chemical Processing: Designed for handling corrosive and hazardous fluids. ⮞ HVAC Systems: Circulate heating or cooling fluids within systems. ⮞Mining: Employed for mine dewatering and slurry handling. ⮞ Power Generation: Circulates cooling water, feeds boilers, and transfers fuel. ⮞ Food & Beverage: Sanitary pumps used for handling milk, juices, and other fluids. ⮞Pharmaceuticals: Precise dosing of chemicals and management of sensitive fluids.

Pump Performance Considerations

Description

Selecting the right pump requires careful consideration of several factors to ensure optimal performance

⮞ Flow Rate (Capacity): The volume of fluid the pump can move per time, typically measured in gallons per minute (GPM) or liters per minute (LPM). ⮞ Head (Pressure): The maximum height a pump can lift fluid, usually measured in meters or feet. ⮞ Viscosity: The thickness of the fluid, influencing the pump type selection. ⮞ Corrosion Resistance: The ability of materials to withstand the fluid’s chemical properties. ⮞ Temperature: Ensuring the pump can handle the fluid's operating temperature. ⮞ Efficiency: Choosing an energy-efficient pump for long-term, continuous use. Proper pump selection, installation, and maintenance are crucial for maximizing efficiency and ensuring reliable operation in both industrial and residential systems.